We have a full-cycle production.

-

Spacious sewing workshops, equipped with modern equipment, both standard and specialised, make it possible to produce a large assortment of products.

-

We have several types of applying images to products. There is silk screen printing, pad printing, thermal transfer, laser engraving, hot stamping.

-

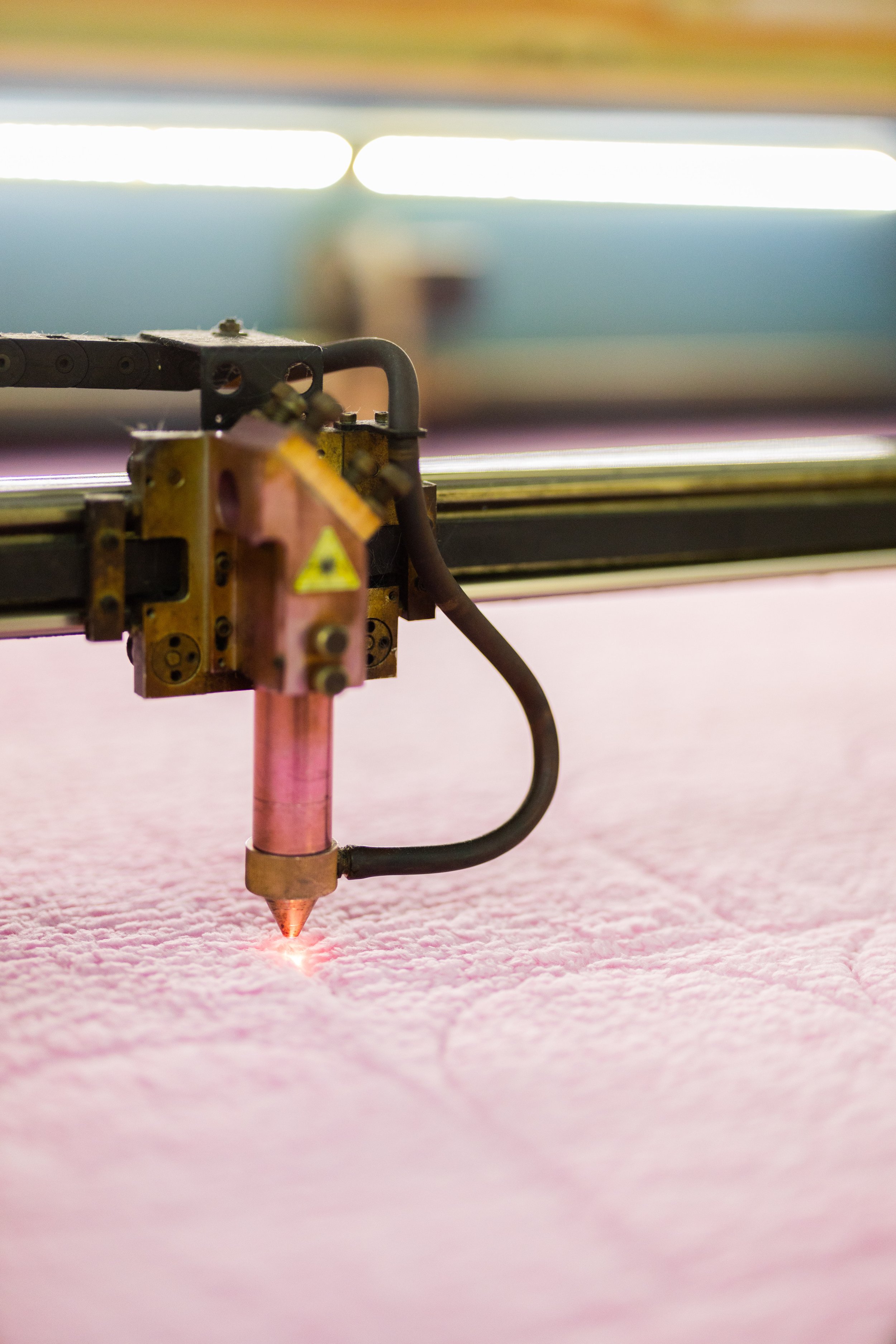

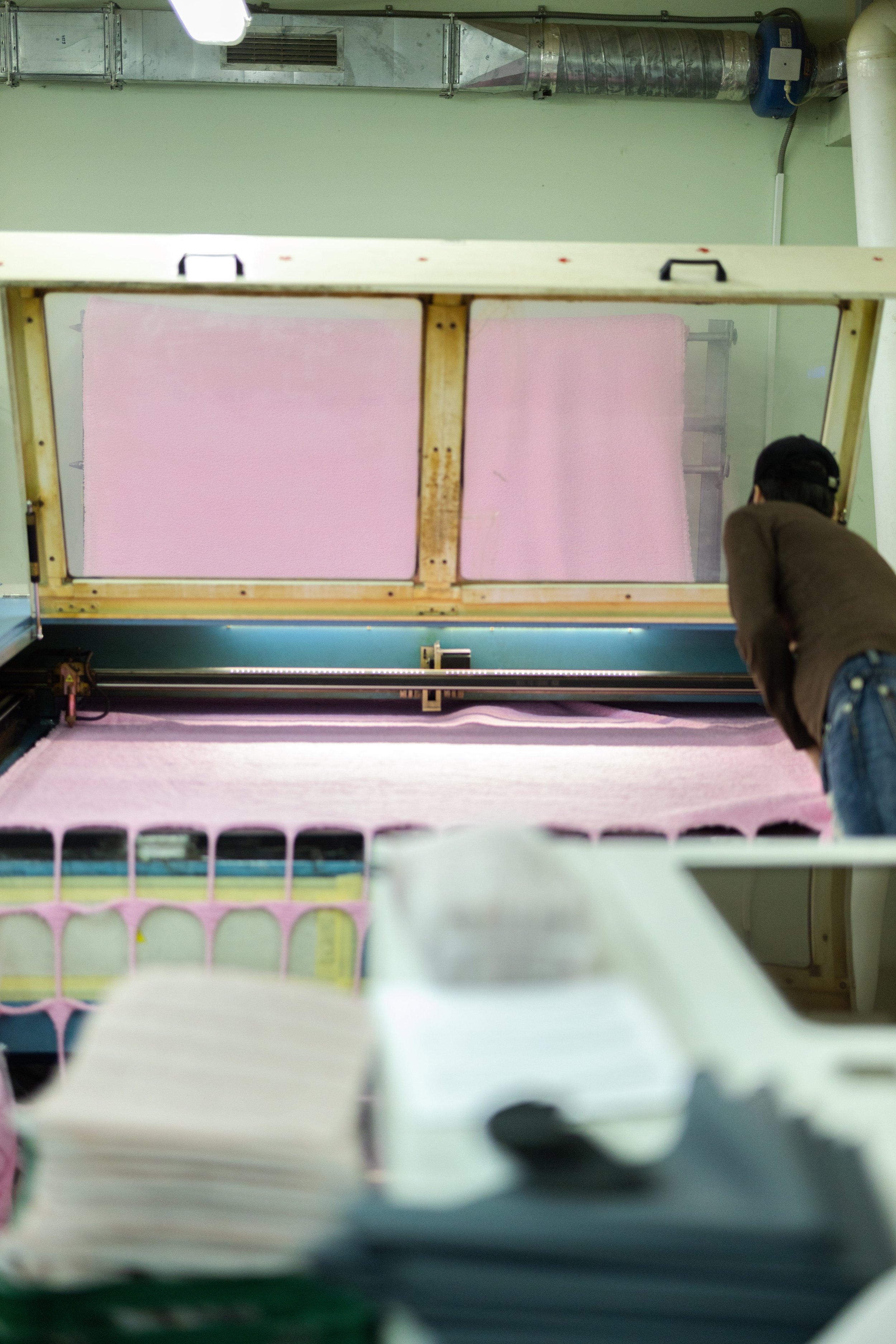

Fabric cutting is done on different equipment depending on the type of material. These are laser cutting machines, cutting presses, and also a layering system.

-

Modern embroidery equipment and high-quality threads allow you to get high-quality embroidery. Our designers and operators have extensive experience in creating and producing complex images on various types of materials.

-

All manufactured products undergo intermediate control during the production process, as well as basic control of the finished product, which minimises the percentage of defective products. Warehouses and the packing workshop are equipped with modern means of accounting and marking of goods, which allows to avoid re-sorting and errors during assembly and packaging of orders.

-

Our company is constantly developing new products both at the request of our clients and on our own initiative. Developers monitor market needs, trends, select and test modern materials. We also regularly buy new equipment that allows us to improve and expand the possibilities of our production.